ABOUT US

Breakthrough

New Fortune

INTRODUCTION

Fuzhou New Fortune Intelligent Technology Co., Ltd. is a professional glass deep processing equipment manufacturer which founded by Fujian Xinfuxing Glass Group in 2003. For 20 years, New Fortune has focused on the development and innovation of glass washing machines, continuously upgrading product performance, and meeting manufacturers’ needs for high efficiency, energy saving, stability, safety, environmental protection, and customization of glass washing equipment.

-

-Founded in 2003

-

-16 years experience

-

-+development and innovation

-

-%Improve product performance

New Fortune

Fortune

OUR PARTNERS

Fortune

NEWS

Service First

-

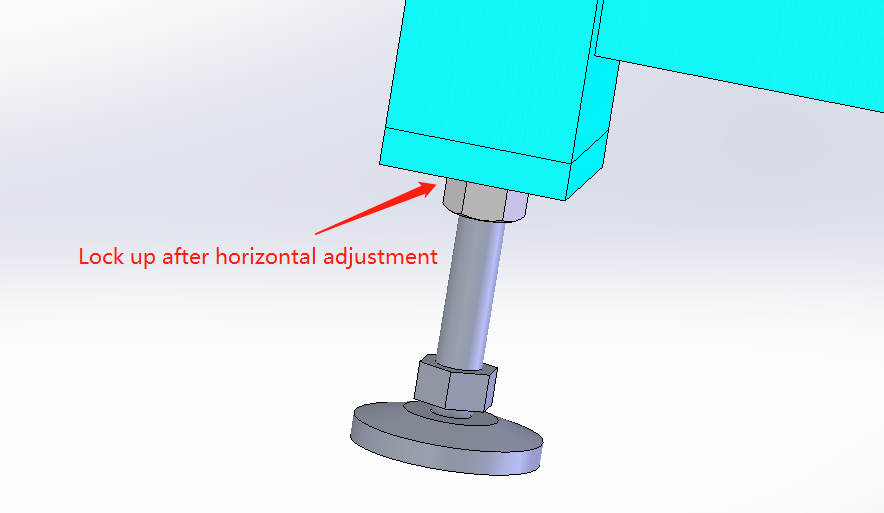

Flat Glass Washing Machine Installation General Insturction

Flat Washer Installation General Instruction 1. The center line of the rubber roller in the infeed conveyor is aligned with the center line of the front equipment. The horizontal line is connected, or according to the site's unilateral connection method. 2. After confirming the placement positio...

-

Glass Thickness Adjustment Instruction

Glass Washing Thickness Adjustment Commissioning Take 3mm thickness glass washing for example Before Washing, 1. Find the Zero Point (Pinch rollers and lower rolllers touch each other) 2. Check the rotation direction of brush and lower rollers When Washing See if 3...