Best quality Glass Washing Machine Before Printing - Bended Glass Washing Machine(Brush Version) – Fortune

Best quality Glass Washing Machine Before Printing - Bended Glass Washing Machine(Brush Version) – Fortune Detail:

Main technical specifications

Glass size: Max 1800 x 2000 mm Min 1000 x 500 mm

Thickness: 1.6-3.2mm

Working height: 1000±50mm(off ground)

Glass flow: Cross feed/ Wing down

Depth of bend: Max 250mm, Min 50mm

Cross curvature: 0-50mm

Conveying speed: 3-10m/min adjustable

Drying speed: 8m/min

Main functions

Remove dust, glove print, pressure mark, etc, dry thoroughly to get glass ready for laminating.

Main features

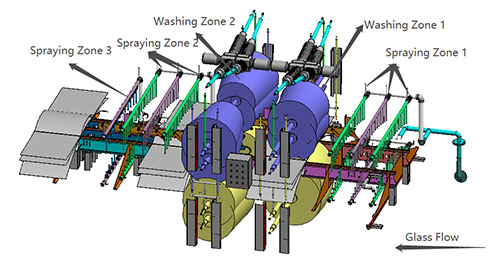

●Two parallel Fenner V belts are used for conveying.

●Sensors are installed at the inlet and outlet of the washing machine to detect the entry and output of the glass. When glass is not in and out within a certain period of time, pumps stop to save power.

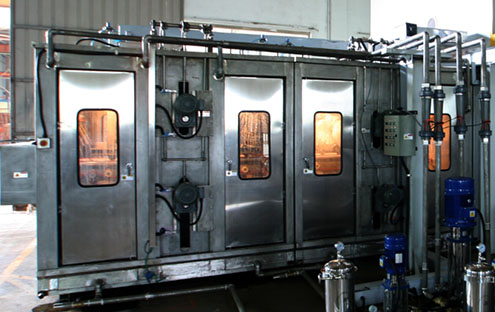

●ashing room is designed as a sealed room to allow better control of water (avoid splashing out).

●The frame and all parts direct or indirect contact with water are made of stainless steel (material 304).

●There are Stainless steel doors (height 2.1mm) with windows (made of laminated glass) at both sides of washing shell which can be open to allow inspection, adjustment and maintenanc

●First pair of brushes design: split to two section - Middle shaft and side cylindrical bristle–liftable and height adjustable

●Second pair of brushes design: split to two section - Middle shaft and side conical bristle–liftable and height adjustable

●Final spray section directly connected to customer’s De-ionized water supply for rinsing before enter drying section.

●Drying section is provided with serval groups of drying air knives depending on dry speed.

●The drying section is equipped with a stainless steel sealed room. It is design as a whole to get better control of air pressure.

●There are stainless steel doors with windows (made of laminated glass) at both sides of drying shell which can be open to allow inspection, adjustment and maintenance

●The angle adjustment of air knives on both sides is controlled by motor, which is convenient for angle adjustment.

●The angle adjustment of air knives on both sides is controlled by motor, which is convenient for angle adjustment.

●Fan chamber includes air distribution room, fan room and air temperature adjustment device.

●Fan equipped with an inverter. According to the inflow of glass, the fan can be turned on or work in lower speed to reduce energy consumption.

●The air inlet of fan room is equipped with a pre-filter and a bag filter. Cleanliness of bag filter can be controlled by a differential pressure controller.

Product detail pictures:

Related Product Guide:

Glass Thickness Adjustment Instruction

Flat Glass Washing Machine Installation General Insturction

Best quality Glass Washing Machine Before Printing - Bended Glass Washing Machine(Brush Version) – Fortune , The product will supply to all over the world, such as: , , ,